-

Table of Contents

Introduction

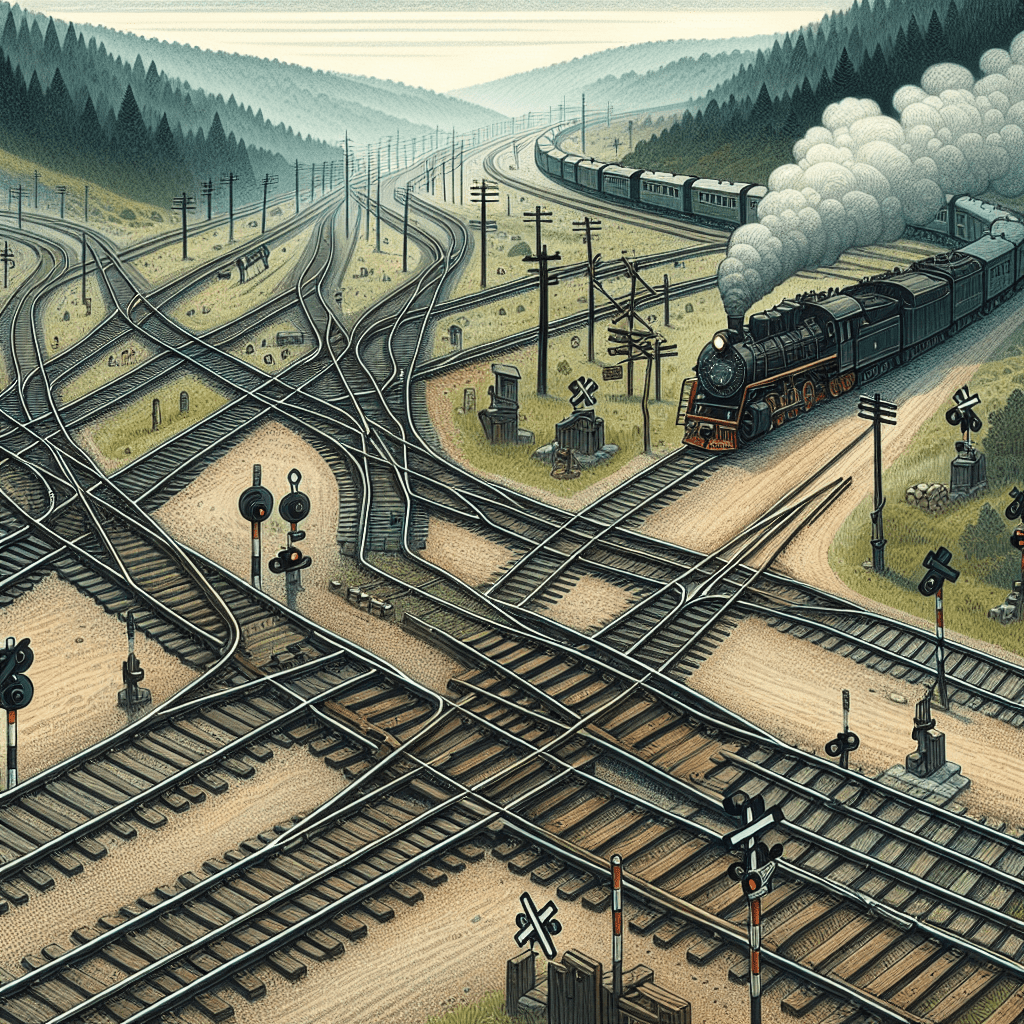

Track switches, also known as railroad switches or points, are critical components in railway systems that enable trains to be guided from one track to another at a railway junction. These mechanical installations consist of a pair of linked tapering rails, known as switch rails or points, and a mechanism to move them. By altering the alignment of the rails, track switches facilitate the safe and efficient routing of trains, allowing for the management of rail traffic and the optimization of network capacity. They are essential for the operation of complex rail networks, enabling trains to change directions, access different routes, and connect to various destinations. Track switches are designed to withstand significant mechanical stress and are equipped with safety features to ensure reliable operation under diverse environmental conditions.

Innovations In Track Switch Technology: Enhancing Railway Efficiency

Track switches, also known as turnouts or points, are critical components in railway systems, enabling trains to move from one track to another. In order to keep train networks running smoothly and efficiently, these devices are essential, serving as the foundation of railway infrastructure. A new age in rail transport has begun with the advent of track switch technologies that greatly improve railway efficiency, safety, and dependability.

The introduction of fully automated and remotely controllable systems is a major step forward in the history of track switch technology. The manual operation of traditional track switches was both time-consuming and error-prone. Now that we live in an automated world, centralized control centers can remotely operate rail switches. Not only does this change improve the speed and accuracy of switch operations, but it also decreases the necessity for on-site workers. Because of this, railways are able to increase service dependability by reducing delays and increasing throughput.

The use of sophisticated sensor technologies and automation have both had a profound impact on the track switch maintenance industry. Integral sensors in track switches can keep an eye on them all the time, spotting signs of wear and tear or possible problems before they cause breakdowns. Railway operators can save maintenance costs and downtime with this predictive maintenance technique that allows them to handle issues proactively. Railroads can keep running smoothly and safely by constantly checking the status of their track switches.

Track switches are more long-lasting and efficient now that smart materials are used in their manufacturing. Improved resistance to mechanical stress and environmental variables has resulted from the incorporation of innovations like shape memory alloys into switch components. The switches’ durability and performance are preserved throughout time because these materials can adjust to different environments, like temperature changes. This results in track switches having a longer lifespan and reducing the frequency of replacements.

Track switch technology has also advanced significantly with the introduction of real-time data analytics. Railway operators may learn a lot about the rail network’s and track switches’ performance by using big data and machine learning algorithms. Train schedule optimization and potential bottleneck identification are both made possible by this data-driven approach, which allows for more informed decision-making. This allows railroads to improve their operating efficiency, which in turn benefits their freight and passenger customers by making their service more reliable.

Also, in line with the worldwide movement towards sustainability, a new trend is developing: track switch systems that incorporate renewable energy sources. One option to lessen the impact on the environment caused by railway networks is to power track switch operations using renewable energy sources like solar panels and wind turbines. Not only does this eco-friendly method help save money, but it also helps preserve the environment.

Finally, the railway sector is undergoing a sea change due to the advances in track switch technology, which are providing several advantages in sustainability, safety, and efficiency. The use of renewable energy sources, predictive maintenance, automated processes, sophisticated materials, and real-time data analytics has led to track switches that are more dependable and efficient than before. The continued development of these technologies will certainly have a significant impact on rail transport in the future, guaranteeing that railways will continue to play an essential part in transportation networks around the world.

The Role Of Track Switches In Modern Rail Safety Systems

For contemporary rail systems to function and be safe, track switches—also called points or turnouts—are essential. The efficient administration of rail traffic is made possible by these mechanical facilities, which allow trains to travel from one track to another. It is impossible to emphasize the significance of track switches in maintaining operating efficiency and safety as rail networks undergo continuous expansion and evolution.

Track switches, first and foremost, are what make rail networks so adaptable. The ability to switch tracks allows trains to go to multiple locations, avoid barriers, and control rail traffic in densely populated places. In complicated rail systems with numerous lines and heavy traffic volumes, this flexibility is especially important for keeping trains running smoothly. Additionally, track switches are critical to the functioning of rail yards, as they enable the assembling and sorting of trains.

Track switches are essential for rail safety and also play a role in traffic control. Trains are guided onto the correct tracks to avoid crashes and derailments when the switches are functioning properly. To do this, contemporary rail networks utilize cutting-edge technologies for the purpose of controlling and monitoring track switches. For example, in order to guarantee that switches are properly aligned before a train passes them, sensors and automated systems are employed to determine their position. By reducing the potential for human mistake, these technologies improve the dependability of train operations.

Furthermore, the integration of track switches with signaling systems is a key aspect of modern rail safety. Signaling systems communicate the status of track switches to train operators, providing them with real-time information about track conditions. This integration allows for the coordination of train movements, reducing the risk of accidents. In addition, automated signaling systems can adjust train speeds and routes in response to the status of track switches, further enhancing safety.

Track switches are vital, but they can become unsafe and less effective over time due to normal wear and tear. So, to make sure they’re reliable, regular maintenance is key. In order to detect and fix problems including misalignment, mechanical failures, and component wear, rail operators perform regular inspections and maintenance. Track switch maintenance is becoming more efficient and effective thanks to advances in predictive maintenance technologies. These systems make use of sensors and data analytics, among others. These technologies provide preventative maintenance by predicting when things might break down, which lowers the likelihood of accidents and interruptions to service.

Additional pressures on track switches have been imposed by the development of high-speed rail networks. Innovations in switch design and materials are necessary for high-speed trains to have switches that can safely operate at higher speeds. The development of reliable and safe switches that can endure the rigors of high-speed operations is an ongoing effort by engineers.

The modern rail safety system relies on track switches, which are an essential component. The smooth functioning of rail networks relies on their assistance in guiding train movements and guaranteeing safety. There will be constant innovation in the design, monitoring, and maintenance of track switches due to the growing relevance of these components in modern rail systems. Rail operators can keep track switches supporting safe and efficient rail operations through integrating sophisticated technologies and implementing rigorous maintenance methods.

Maintenance Strategies For Optimal Performance Of Track Switches

Track switches, also known as turnouts or points, are critical components in railway infrastructure, enabling trains to change tracks and facilitating the efficient management of rail traffic. Ensuring their optimal performance is essential for maintaining the safety and reliability of rail operations. Consequently, effective maintenance strategies are paramount to prevent failures that could lead to costly disruptions or accidents. To achieve this, a comprehensive understanding of the various maintenance approaches is necessary.

One of the primary strategies for maintaining track switches is regular inspection. Routine inspections allow for the early detection of wear and tear, misalignments, and other potential issues. By employing advanced diagnostic tools, such as ultrasonic testing and thermal imaging, maintenance teams can identify hidden defects that may not be visible to the naked eye. These technologies provide valuable data that can inform maintenance decisions, allowing for targeted interventions that address specific problems before they escalate.

In addition to inspections, preventive maintenance plays a crucial role in ensuring the longevity and functionality of track switches. This approach involves scheduled maintenance activities, such as lubrication, cleaning, and component replacement, based on the equipment’s usage and environmental conditions. By adhering to a preventive maintenance schedule, railway operators can minimize the risk of unexpected failures and extend the lifespan of track switches. Moreover, this proactive approach can lead to cost savings by reducing the need for emergency repairs and minimizing downtime.

Another important aspect of track switch maintenance is the implementation of condition-based maintenance (CBM). This strategy relies on real-time data collection and analysis to determine the actual condition of track switches. By utilizing sensors and monitoring systems, railway operators can continuously assess the performance of track switches and make informed decisions about when maintenance is required. This data-driven approach allows for more precise maintenance planning, reducing unnecessary interventions and optimizing resource allocation.

Furthermore, the integration of predictive maintenance techniques can significantly enhance the effectiveness of track switch maintenance strategies. Predictive maintenance leverages machine learning algorithms and historical data to forecast potential failures before they occur. By predicting when a track switch is likely to fail, maintenance teams can schedule repairs at the most opportune times, thereby avoiding service disruptions and improving overall system reliability. This forward-looking approach not only enhances safety but also contributes to more efficient railway operations.

In addition to these technical strategies, effective communication and collaboration among maintenance teams are essential for the successful implementation of maintenance plans. By fostering a culture of teamwork and information sharing, railway operators can ensure that all stakeholders are aligned in their efforts to maintain track switches. Regular training and development programs can further enhance the skills and knowledge of maintenance personnel, enabling them to stay abreast of the latest technologies and best practices in track switch maintenance.

In conclusion, the optimal performance of track switches is vital for the safe and efficient operation of railway systems. By employing a combination of regular inspections, preventive maintenance, condition-based maintenance, and predictive maintenance, railway operators can effectively manage the maintenance of track switches. These strategies, supported by advanced technologies and a collaborative approach, ensure that track switches remain in optimal condition, thereby enhancing the overall reliability and safety of rail networks. As the railway industry continues to evolve, the adoption of innovative maintenance strategies will be crucial in meeting the growing demands for efficient and reliable rail transportation.

Q&A

1. **What is a track switch?**

A track switch, also known as a railroad switch or turnout, is a mechanical installation that enables trains to be guided from one track to another at a railway junction.

2. **How does a track switch work?**

A track switch operates by using movable rails, called points or switch rails, which can be shifted to direct a train from one track to another. The switch is controlled either manually or automatically, often using a lever or a motorized mechanism.

3. **What are the main components of a track switch?**

The main components of a track switch include the switch rails (movable rails), stock rails (fixed rails), a frog (where the tracks cross), guard rails (to keep wheels aligned), and the operating mechanism (manual lever or motor).

Conclusion

Trains are able to be guided from one track to another at a railway junction by means of track switches, which are also called railroad switches or points. The train can be guided onto different tracks by adjusting a set of rails called switch rails. Efficient administration of rail traffic relies on the operation of track switches. These switches enable train routing, rail yard operations management, and the facilitation of complicated rail networks. Any failure might cause major interruptions or accidents, so it’s important to maintain them properly and inspect them regularly to make sure they’re safe and reliable. Railway operations are now more efficient and safer because to technological advancements like automated and remotely controlled switches. In a nutshell, contemporary rail systems couldn’t function without track switches.